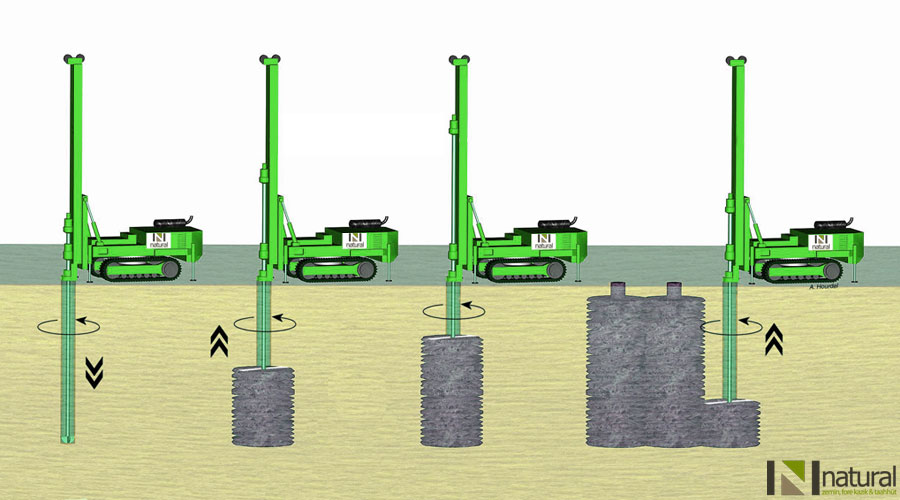

It creates cylindrical ground-concrete columns on the ground with the cement injection jet pumped in a “controlled” way and under “high pressure”. It allows for improving current grounds and uncontrolled filling and creating a cement/ground screen which functions for reliance and impermeability.

On loose grounds where ground water level is high, jet grout for ground improvement offers economic advantages. Jet Grout is also applied for impermeability in sheathing systems on grounds where ground water is concentrated.

Jet grout is applied in 3 different systems, namely jet 1 (mono jet) where shearing and filling is only made with the injection jet, jet 2 (double jet) where mono jet is supported with the air bag and jet 3 (triple jet) where water is used in addition.

The jet grout equipment is comprised of a suitable driller, a special high pressure pump unit, mixer unit and cement silo.

Jet Grout column is obtained by filling and compressing the gaps in the ground with the mixture of water and cement sprayed at 400-600 bar pressure. Water-cement mixture ruptures the ground, combines with the ground and creates the cement ground structure.